Who We Are

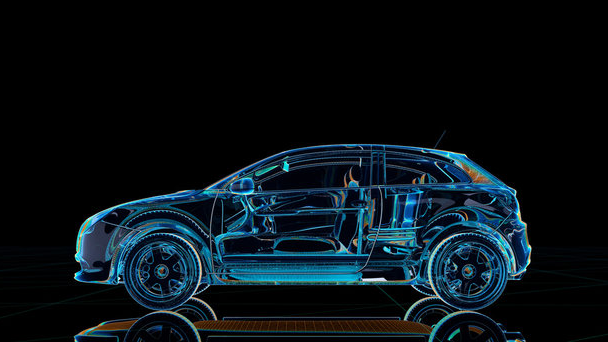

Advocates for progress and catalysts for innovation. Our team is made of individuals, each with a unique set of skills and boundless ingenuity , united in their dedication to pushing the boundaries of technology forward.

WHO WE ARE

Forward-thinkers with a passion for progress.

3D4Life is dedicated to providing sustainable 3D manufacturing solutions to our clients. With our extensive expertise and unique toolset, we help our clients bring their ideas to life and achieve their goals. Our team is comprised of highly skilled and experienced professionals who are passionate about innovation and always striving to push the boundaries of what is possible. We believe in building strong relationships with our clients and working closely with them to understand their unique needs and deliver solutions that exceed their expectations.

Whether you’re looking to enhance your current manufacturing process or develop a new product from scratch, we are here to help you every step of the way.

OUR MISSION

Drive innovation. Deliver solutions. Help pave the path to tomorrow’s technology.

Design and provide distinct sets of tools and workflows for advanced 3D manufacturing.

Ensure sustainable designs.

RECYCLING

An integral part of our supply chain.

3D printing has revolutionized the way we manufacture products, but it can also generates a lot of waste. Failed or returned products could end up in landfills, contributing to environmental degradation. This is where 3D 4 Life comes in.

3D 4 Life is a company that specializes in recycling failed or returned 3D prints into new products. Rather than disposing of these prints, our company shreds them and turns them into filament or pellets that can be used to create new 3D prints. This process not only reduces waste but also helps to conserve resources by using recycled materials.

One of the unique features of 3D 4 Life’s products is the inclusion of recycling symbols and/or QR codes embedded within the prints. This allows us to easily identify the type of material used in the print and how to recycle it properly. This feature aligns with the company’s commitment to promoting sustainable practices and reducing environmental impact.

3D 4 Life’s recycling process involves several steps. First, the failed or returned prints are shredded into small pieces. The shredded material is then cleaned and sorted by type. Once sorted, the material is melted and extruded into filament or pellets that can be used to create new 3D prints. The resulting filament or pellets is of high quality and can be used with all our 3D printers.

Overall, 3D 4 Life is a company that is dedicated to reducing waste and promoting sustainability in the 3D printing industry. By recycling failed or returned prints, we are making a positive impact on the environment while also providing high-quality products to our customers.

MEET OUR TEAM

Our team comprises individuals with diverse backgrounds and areas of expertise, each offering a distinctive viewpoint to the organization. As our paths intersected over time, we recognized and appreciated each other’s skill sets, and united to tackle intricate problems in the 3D manufacturing sector.

Tim Murphy

Founder

Technology leader with a diverse background across disciplines and locations.

Zee Chaudhari

Founder

Experienced technology consultant and sales executive with an extensive track record of leading his clients to new heights in innovation. Holder of a B.Eng. in Material Science and Engineering with years of experience in the field of advance manufacturing.

Don Smith

Founder

Accomplished Operations, Shared Service and Supply Chain Transformation Leader

Expertise in Procurement | Global Operations Management | Strategic Planning and Execution